| Why We Build with Earthbags by Kaki Hunter and Doni Kiffmeyer |

We started by teaching ourselves how to make adobe bricks, the most common earthbuilding technique native to the U.S. Making adobe bricks turned out to be a lengthy process that involved mixing the mud, pouring it into forms, lifting the forms, and then turning the blocks over the next several days to facilitate even curing. The blocks then had to be stacked and protected until ready for use. Manufacturing the adobes required a considerable amount of space for both the pouring process, as well as for storage of the dirt needed to make them, and then the storage of the adobe bricks themselves until they were ready for building. We live right in the heart of a small town, which made this process a little tight. The dirt for adobe block and most other forms of earthen architecture require a specific ratio of clay to sand, ideally about 25 to 30 percent clay to 75 to 70 percent well-graded sand. In some cases, a stabilizing agent may be added to an earthen soil to increase its compressive strength and make it resistant to the affects of water. Some earth building techniques like cob require copious amounts of straw fiber added to the mix. In most cases, adobe brick also benefits from the addition of straw or some other kind of natural fiber.

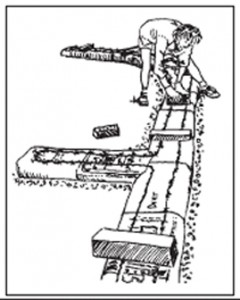

Earthbags (as we were soon to discover) had the advantage of being able to use a wider range of soil types than traditional earth building techniques - "Wow, this dirt's just got five percent clay and it still works!" We have been able to adapt soils for use in earthbags that have ranged from zero clay to 50 percent clay content. No type of fiber was needed within the soil. Since the bag acts as a textile container for the earth, the woven fibers do the job of stabilizing the soil in place so the soil can have a lesser quality binding strength than required for most other types of earthen construction. When necessary, even dry sand can be used as fill, as could be the case in providing emergency relief shelter. The Earthbag System is a contemporary form of earthen construction that uses modern woven polypropylene feedbags (usually misprints) or long tubes as a flexible textile container (or what we call a flexible form) preferably filled with dampened soil. The bags or tubes are filled in place on the wall being built so there is no heavy lifting. After a whole row is laid, the bags are compacted from above with hand tampers. The compacted earth later cures to a cement-like hardness. Two strands of four-point barbed wire are laid in between every row that act as a "Velcro" hook-and-latch mortar, cinching the bags together while providing continuous built-in tensile strength. Tensile strength inhibits the walls from being pulled apart during stressful conditions like earthquakes, floods, hurricanes, and load-bearing and lateral forces. The combined strength of the four-point barbed wire sandwiched in between the woven textile fabric of every row of earthbags adds a significant degree of tensile resilience that is lacking in most traditional forms of earthen architecture.

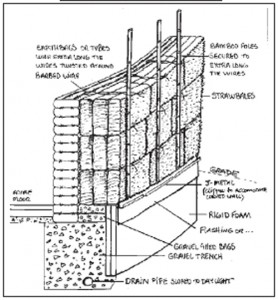

Building the earthbags around temporary rigid box and arch forms creates door and window openings. After compaction of the keystone bags, the forms are then removed. Wood-strip anchors are installed during the wall-building process, providing an attachment for bolting on doorjambs, cabinetry or wood-frame intersecting walls, electrical outlets and plumbing systems. Wall plastering options range from thick natural earthen plaster applied directly over the surface of the bags (yes, it sticks!) or, for additional protection, lime plaster can be applied over an earthen plaster. Cement/lime based plasters perform well when the earthbags are filled with a stable, well-draining sandy soil and applied over stucco mesh (chicken wire). Plasters can be applied by hand or sprayed on with a pressurized plaster sprayer for a unique contoured effect that accents the shape of the bags or tubes. Earthbag Architecture can be designed to suit a wide variety of climates. Since the woven polypropylene bags are virtually rot proof, earthbags are an excellent choice for underground structures: root cellars, storm shelters, bermed homes and greenhouses. In climates where wood is scarce, whole houses can be built exclusively with earthbags including the foundation and roof, as is the case for corbelled earthbag domes. Earthbags also combine well with other natural building materials that can be combined together to create hybrid structures. Straw bales can be interlocked with earthbags to build sturdy arch entryways or to add thermal mass to the interior wall of an attached sunroom. Or we may choose to use earthbags for the sunken first level of a structure and then switch to strawbale, post-and-beam, cob or adobe brick for the rest of the wall above grade to make use of an available resource or add aesthetic variety.

Building codes The earthbag building system has been extensively tested by Nader Khalili in conjunction with the ICBO (International Conference of Building Inspectors) and the Hesperia Building Department in Hesperia, California, at the California Institute of Earth Art and Architecture for earthquake resilience, loadbearing, and shear strength stability, all of which were proven to far exceed conventional code standard acceptance. Resources Sources for bags and tubes can be found on the Internet under woven polypropylene feed bags. Our favorite U.S. supplier for both pillow-pack and gusseted misprint bags is www.innpack.com, toll-free 800.622.3695 in Tennessee. Typical prices for 50-lb misprints are approximately $.17 each (USD), and 100-lb bags are $.25 each (USD). Both come in bales of 1,000 bags. Smaller quantities for bags and tubes are available from a Kansas City, Missouri, source www.centralbagcompany.com 816.471.0388. Ask for Chris Klimek for prices and selection. Also try 800.521.1414 www.fultonpacific.com. For step-by-step nitpicking details about building with earthbags, check out our book Earthbag Building, the Tools Tricks and Techniques by Kaki Hunter and Donald Kiffmeyer, New Society Publishers, 2004. Donald Kiffmeyer and Kaki Hunter have been involved in alternative construction since 1993, specializing in affordable, low impact and natural building methods. Inspired by the work of visionary architect Nader Khalili, the grandfather of Sandbag/ Superadobe/Earthbag architecture, they wrote a screenplay entitled "Honey's House," a film about truth, justice and affordable housing. From these innocent beginnings, they were launched into the alternative building movement where they were encouraged to share their combined innovations to establish the Flexible Form Rammed Earth technique. Together they co-authored the book Earthbag Building, the Tools, Tricks and Techniques by New Society Publishers. They live in Moab, Utah, where they continue to focus on the research and development of fun, quick, simple and solid natural and alternative building techniques that are inspired by this fabulous planet. |

We live in the heart of the great Southwestern United States, surrounded by examples of one-thousand-year-old ruins left behind by the ancient civilizations of the Anasazi, Hohokam, Pueblo and many others. It was these original natural builders that inspired us to consider building with earth as a way to create beautiful, low-impact, energy-efficient housing that has endured the test of time to this day.

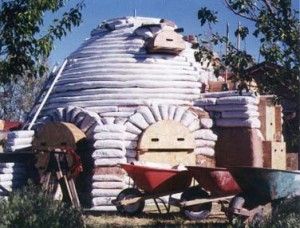

We live in the heart of the great Southwestern United States, surrounded by examples of one-thousand-year-old ruins left behind by the ancient civilizations of the Anasazi, Hohokam, Pueblo and many others. It was these original natural builders that inspired us to consider building with earth as a way to create beautiful, low-impact, energy-efficient housing that has endured the test of time to this day.  After our initial foray into homemade adobes, we read about the work of international award-winning architect Nader Khalili. Nader is an Iranian-born architect who abandoned a successful career designing skyscrapers to follow his heart, which led him to create an innovative sandbag/superadobe/earthbag architecture as a means of providing low-tech, enduring affordable housing. Inspired by the ingenious monolithic adobe buildings of his homeland of Iran, Nader conceived the idea of building domed and vaulted structures with.bags of earth. We took a one-day workshop with Nader and we were hooked! We returned home excited to build our first earthbag-wall project, a privacy wall opposite the busy baseball field across from our house. However, our interest quickly zeroed in on the building process itself. We began innovating tools, tricks, and techniques that we felt made the building process more enjoyable and the results cleaner and predictably solid. We coined the acronym FQSS which stands for Fun, Quick, Simple and Solid. The process has to be Fun, which makes the work go Quickly as long as the procedure is kept Simple and the end results are Solid. Hence the FQSS stamp of approval became our dirtbag golden guideline.

After our initial foray into homemade adobes, we read about the work of international award-winning architect Nader Khalili. Nader is an Iranian-born architect who abandoned a successful career designing skyscrapers to follow his heart, which led him to create an innovative sandbag/superadobe/earthbag architecture as a means of providing low-tech, enduring affordable housing. Inspired by the ingenious monolithic adobe buildings of his homeland of Iran, Nader conceived the idea of building domed and vaulted structures with.bags of earth. We took a one-day workshop with Nader and we were hooked! We returned home excited to build our first earthbag-wall project, a privacy wall opposite the busy baseball field across from our house. However, our interest quickly zeroed in on the building process itself. We began innovating tools, tricks, and techniques that we felt made the building process more enjoyable and the results cleaner and predictably solid. We coined the acronym FQSS which stands for Fun, Quick, Simple and Solid. The process has to be Fun, which makes the work go Quickly as long as the procedure is kept Simple and the end results are Solid. Hence the FQSS stamp of approval became our dirtbag golden guideline.  The soil we selected for our initial earthbag building projects was delivered from our local gravel yard at 80 cents per ton. That was ten years ago. Today we pay about $1.80 per ton. Reject sand or crusher fines are common names for the clay fines that are the byproduct from the manufacture of washed sand and gravel produced at most developed gravel yards. Often, this reject material has sufficient clay-to-sand ratio to produce strong compacted earthen blocks. However, over the years, we have had considerable success with using almost any type of soil available on site by paying particular attention to adjusting the moisture-to-soil ratio that produces the optimal strength block.

The soil we selected for our initial earthbag building projects was delivered from our local gravel yard at 80 cents per ton. That was ten years ago. Today we pay about $1.80 per ton. Reject sand or crusher fines are common names for the clay fines that are the byproduct from the manufacture of washed sand and gravel produced at most developed gravel yards. Often, this reject material has sufficient clay-to-sand ratio to produce strong compacted earthen blocks. However, over the years, we have had considerable success with using almost any type of soil available on site by paying particular attention to adjusting the moisture-to-soil ratio that produces the optimal strength block.  Insulation strategies for earthbag walls offer a variety of options. Narrow tubes provide a sturdy load-bearing wall with plenty of thermal mass, while straw bales secured to the exterior of the wall provide ample insulation. Now, we have mega mass coupled with mega insulation to provide the best use of both of these materials in one building. Another way to add interior mass is to build our interior walls with earthbags and our exterior walls with straw bales alone. Another approach we have experimented with is mixing a percentage of 3/4-inch pumice to a quality rammed earth soil that captures air spaces within the earthbag itself. A 50/50 mix of suitable earth and pumice make the bags one third lighter than their normal all dirt weight yet still makes a nice hard compacted earthbag.

Insulation strategies for earthbag walls offer a variety of options. Narrow tubes provide a sturdy load-bearing wall with plenty of thermal mass, while straw bales secured to the exterior of the wall provide ample insulation. Now, we have mega mass coupled with mega insulation to provide the best use of both of these materials in one building. Another way to add interior mass is to build our interior walls with earthbags and our exterior walls with straw bales alone. Another approach we have experimented with is mixing a percentage of 3/4-inch pumice to a quality rammed earth soil that captures air spaces within the earthbag itself. A 50/50 mix of suitable earth and pumice make the bags one third lighter than their normal all dirt weight yet still makes a nice hard compacted earthbag.