by Kelly Hart

The Jordan Heritage Revival Company (JHRC), in association with the King Abdullah II Fund for Development, has requested assistance in training several Jordanians in the art of building structures with earthbags. As part of this training, they propose that a demonstration project be built near the Montreal Hotel, located at Shobak, not far from Petra, Jordan. Specifically they would like to build two small staff residential units, one large meeting room, and a storage facility on that site.

Kelly Hart, the founder of www.earthbagbuilding.com, www.greenhomebuilding.com, and other websites related to sustainable architecture, has responded to this request for a trainer and is currently negotiating with JHRC to provide the necessary training. Kelly built his own home using the earthbag technique. He has produced a video, titled Building with Bags: How We Made Our Experimental Earthbag/Papercrete House, which chronicles his adventure in building this house, and shows other earthbag houses as well. He also produced a video program titled A Sampler of Alternative Homes: Approaching Sustainable Architecture. Kelly has had a lifelong interest in building and has worked in construction professionally. He has coordinated other earthbag training projects, including the building of a Glorieta in Colorado, USA, a model home in Puerta Vallarta, Mexico, and a small dome in San Juan Cosala, Mexico.

Kelly Hart, the founder of www.earthbagbuilding.com, www.greenhomebuilding.com, and other websites related to sustainable architecture, has responded to this request for a trainer and is currently negotiating with JHRC to provide the necessary training. Kelly built his own home using the earthbag technique. He has produced a video, titled Building with Bags: How We Made Our Experimental Earthbag/Papercrete House, which chronicles his adventure in building this house, and shows other earthbag houses as well. He also produced a video program titled A Sampler of Alternative Homes: Approaching Sustainable Architecture. Kelly has had a lifelong interest in building and has worked in construction professionally. He has coordinated other earthbag training projects, including the building of a Glorieta in Colorado, USA, a model home in Puerta Vallarta, Mexico, and a small dome in San Juan Cosala, Mexico.

The above image illustrates the basic proposed concept. There would be two independent domes serving as residential units. The central structure would be two stories high, with the lower level being used for storage and the upper level a large meeting room. All of these buildings would be recessed into the hillside so that the dark brown portion on the central structure represents the eventual ground level. Entrance to the meeting room would be from the ground level at the upper, curved side.

One reason for the variety of shapes is that this will give the trainees experience in several aspects of earthbag building, allowing them to understand the broad range of building designs that can be done using earthbags. Additionally, several different types of bag material and techniques for reinforcing the structures will be utilized, giving even more experience. For instance, one of the domes would be built using individual bags, while the other would be built using long tubes of bag material. The lower portion of the central building would be made with somewhat larger tubes, and the upper part would built with long tubes of open mesh material.

Experience in proper buttress design, and other seismic reinforcement techniques will be part of the project. The two story structure will demonstrate both curved and straight vertical wall building, as well as how to go about designing for more than one story. Techniques for proper berming into the earth and waterproofing the buildings will be shown. A variety of plaster techniques, using both cement and earthen materials will be part of the project.

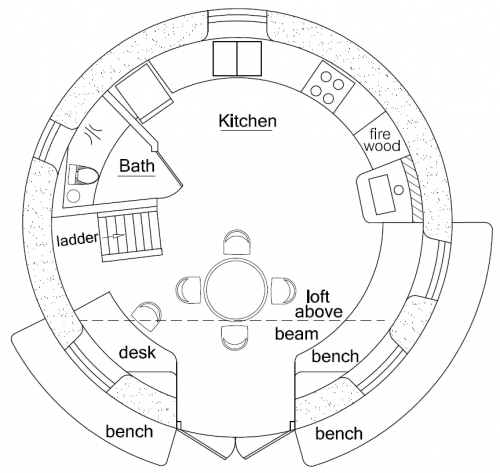

The above floor plan shows one possible arrangement for the interior of the domes. This dome would measure approximately 6 meters in interior diameter, and provide all of the necessary functions for normal living, with a small kitchen, bathroom, living and dining space on the main level. An upper loft (accessible via steps) would provide sleeping space. The total interior living area would be approximately 42 square meters.

The dome built with individual bags would look something like this as it is being built, only with a larger diameter. Windows can be formed in many ways, including with circular forms like shown here.

The dome built with individual bags would look something like this as it is being built, only with a larger diameter. Windows can be formed in many ways, including with circular forms like shown here.

The arched doorway is built over a simple form which is then taken away and can be reused. Domes of this sort can provide complete shelter with practically no wood or steel; often only the soil from the site is needed to fill the bags. Tarps are used to protect the bags from sunlight until they can be plastered.

Another approach to building domes is with continuous tubing that is available in large rolls of material. At right is an example of such a dome. If built properly, domes of this sort can be extremely stable in case of earthquakes, high winds, or other environmental hazards.

As shown below, finished domes can be quite beautiful as well as practical and economical. Dome technology, especially in an arid climate like Jordan, can provide simple shelter that is quite ecological. Most of the work in building these can be done by unskilled labor.

For the other two-story building, I think the closest example of something that has already been built is perhaps the residence designed a Colombian architect and built in that country. While it is only one story, it combines both curved and straight vertical walls (along with domes), and has a flat, concrete roof.

The poured concrete second story floor and roof were made with techniques that I am sure are familiar to contractors throughout Jordan, using standard reinforcement wire mesh and temporary supports beneath the pour, as shown below.

Below is what the final building looked like after being plastered.

This method of building can conceivably eliminate the need for the barbed wire placed between all courses of bags in more traditional earthbag building. This can make construction go faster and cost less.

In the photo below you can see how the walls are being tamped into place on one of his projects. The tubing is gathered onto a long funnel and is moved along as it is filled with the soil, a very simple process.

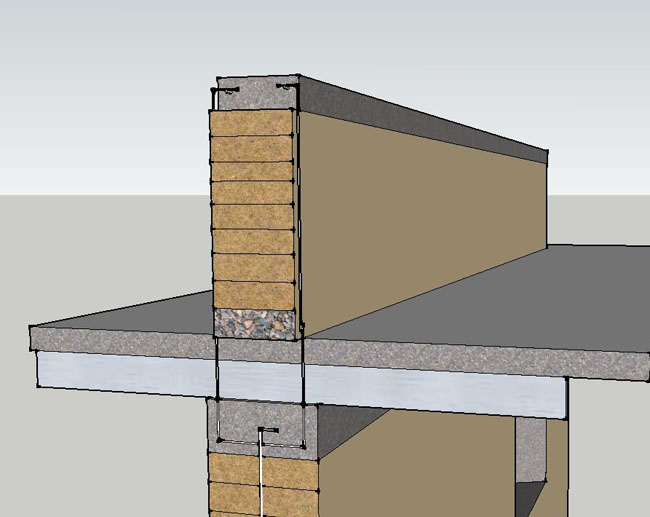

In order to reinforce the second story and make it safe from earthquake damage, I propose that we employ a design offered by a licensed engineer for earthbag building, as illustrated below. The wall basically gets confined between periodic vertical steel posts, which in turn are embedded in concrete bond beams at the top and bottom.

In the picture below you can see a worker applying lime plaster to an interior wall of the Puerta Vallarta model home. The plaster mesh is visible on the portion of the wall that has not yet been plastered.

The next photo shows a finished project that was built in Jordan, the Qusayr al-Jawasreh Community Center in South Shounah near the Dead Sea. The two domes were made with earthbags. You can learn more about this project on this page.

There are still many more details to design, as well as formulating a materials list for this project, but at least this overview gives you some idea of the scope and intention of the project.