| Low-Cost Multipurpose Minibuilding by Owen Geiger from www.motherearthnews.com |

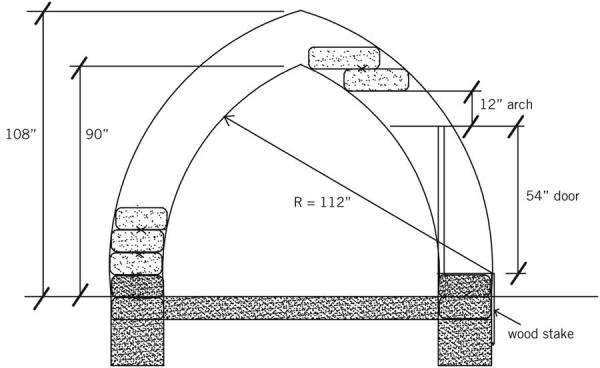

One of the most practical structures on a small farmstead is a multi-purpose garden structure that can serve as a storage shed or cool pantry above ground, or as a root cellar or storm shelter below ground. You can build this multipurpose structure for about $300 using earthbag construction (bags filled with earth and stacked like bricks). And the skills you learn by building the dome will serve you well if you plan to build a larger earthbag structure or even an earth home. This earthbag shed is 8 feet in diameter inside (about 11 feet outside) and approximately 8 feet high. Plans could be scaled up to create 10- to 16-foot diameter domes. At the top of a larger dome, the earthbag thickness and cantilever (corbel distance) have to be adjusted slightly so it's more conical.

There are several building options:

The first two courses of bags are complete circles bonded with barbed wire. Succeeding courses start at either side of the door opening. Orient the building so the door is opposite prevailing storms and wind. Create a slope in front of the dome so water drains away from the door.

String lines: The center string line establishes the circular shape and is lengthened accordingly to measure each course. The string line that establishes the vertical dome curvature remains a constant length of 112 inches.

Bag filling: You can fill the bags using heavy-duty 2-gallon plastic buckets, which are small enough to handle comfortably. Most bags need four buckets of road base to be filled to capacity. In some cases, only three buckets of road base are necessary to make a shorter bag to avoid ending a bag above a previous joint. Two rounded shovelfuls of road base fill a 2-gallon bucket perfectly. Or use a sturdy hoe or similar digging tool to reduce shoveling. Even though shoveling is faster, it's easier to pull the material into a bucket than to lift the material with a shovel. On the last stroke, a quick flick of the hoe will tilt the bucket upright. To keep bags open when filling, use a "bucket chute," a funnel made by cutting the bottom inch off of a 4-gallon bucket.

Leveling: Usually just a few bags per course required a little extra tamping. I attribute this to measuring the contents of each bag and placing them with a bit of care. Arch form: We experimented with old tires to form the door arch, because the time and cost of building a curved form with plywood didn't make sense. We used wood supports under each side of the tires, which were braced side-to-side. This created an opening so we could check the curvature with the string line. Owen Geiger is the co-developer of Earthbagbuilding.com and Director of the Geiger Research Institute of Sustainable Building.For a complete version of this article see www.motherearthnews.com. |

Tamping: We used two tampers: an agile 45-inch one for tamping bag contents during filling, and a 55-inch one. Both can be used for tamping walls, but the long-handled version is easier to apply more force. Each one is made with a 6-by-6-by-3/8-inch plate-steel base, 3/8-inch angled steel ribs, and a 1 3/4-inch pipe to hold the wood handle, which is bolted on. You could also buy one for about $10.

Tamping: We used two tampers: an agile 45-inch one for tamping bag contents during filling, and a 55-inch one. Both can be used for tamping walls, but the long-handled version is easier to apply more force. Each one is made with a 6-by-6-by-3/8-inch plate-steel base, 3/8-inch angled steel ribs, and a 1 3/4-inch pipe to hold the wood handle, which is bolted on. You could also buy one for about $10.